AESTHETIC, BEAUTIFUL AND SAFE

Glass has long had a fixed place as a building material and means of design in architecture. With Glas Marte GM RAILING® you can literally lean far out in building planning, because we have the ideal solution for every requirement – whether GM GLASS RAILINGS for patio, balcony, stairs or French window.

Safety plays an important role, especially when it is important to limit open spaces. Both outdoors and indoors, all-glass railings are a reliable anti drop device. With the GM RAILING® series you can find the right solution for all requirements.

We are pleased to share the following GM GLASS RAILINGS information with you here:

- Glass railing application possibilities

- Advantages of glass railings – all-glass railings

- Prices/costs: Glass railings – all-glass railings

- Range of services

- Glass railings for balconies

- Glass railings for patios

- Glass railings for stairs

- Glass railings – the series

- Installation of glass railings

- Safety with your only-glass railing

- Accessories for your glass railing

AESTHETICS AND FUNCTIONALITY THAT CONVINCE

Glass railings allow ideal use of your outdoor area in terms of space and time and create an individual and protected ambience in conjunction with the surrounding area to linger and feel good. Where less transparency is desired, the glass railing can also serve as a sight screen by special processing of the glass. All possibilities are open to you.

The GM RAILING® glass railing system from Glas Marte is suitable for private and public construction projects. GM RAILING® offers a wide range of optimised series for the indoor and outdoor areas. The all-glass railings impress with their versatile application possibilities. Based on nine basic types — whether on top, at the side, flush, curved, on a parapet or on steel beams, etc. – almost all requirements can be realised via numerous variants and special designs.

Handrails, edge protection, glass edge protection with a glass rod and mounting structures are neatly finished and feature a minimalist design.

All series are quick and easy to install, as the prefabricated glass construction modules are only hooked into the substructure profiles to be installed on the building site and screwed together with cylinder-head screws or special spacers. This screwing allows a tolerance compensation of the vertical position at tie-bar height. Due to clamping in the support rail, no glass holes are necessary. This reduces planning and installation work as well as costs. Systematisation can generate benefits in all areas, especially the required static proof.

ADVANTAGES OF GLASS RAILINGS

The smooth glass surface without uprights, cross bars and pillars prevents injury. It makes it difficult for children to climb on and over it. There is no longer any desire to do so due to the view. Older people, on the other hand, prefer the bright floor surfaces without shadows and the clarity. The only-glass railings are easy to care for, smooth and pleasant to the touch. In addition, all-glass railings provide protection: Sound insulation and wind protection due to glass railings are often highly valued. Last but not least, the aesthetics speak for GM RAILING®: Glass railings take a back seat visually and show the space, not the barrier. They are light, modern and open to views, non-verbal conversation and light.

In a nutshell:

- Fall protection – especially for children (hard to climb over)

- Uniform facade image

- Railings made of glass do not distract. Glass instead of lattice fences.

- An invisible architectural element that gives the building elegance and expression

- Spatial effect and a more transparent building

- Much friendlier and lighter impression due to the incidence of light

- Colours, motifs and/or lighting

- Protection against increased solar radiation

- Protection against prying eyes and sound insulation

- Dirt-repellent

- Easy care and maintenance

- Keeps out wind and weather

Advantages of the module principle

- Infinite adjustability

- Tested glass railing series

- All proofs tested according to DIN 18008-4/Cat. B.

- Detail database/hundreds of design options

- Technical elaboration

- Optimal cavity-free glass support

- Uniform bedding without high stress peaks

- Individual dimensions according to customer requirements

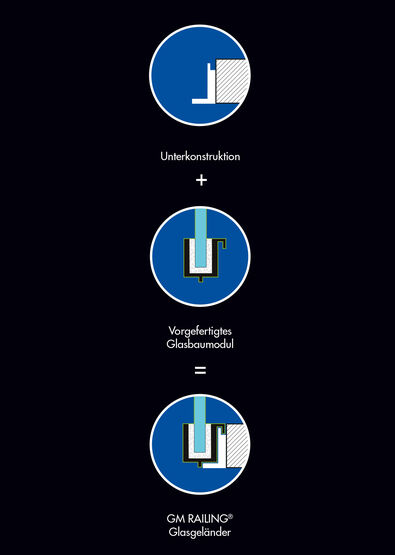

THE PRINCIPLE

The GM RAILING® all-glass railing consists essentially of a glass construction module (glass & profile already bonded together in the factory) and a substructure profile.

Due to the supply of the glass construction module (glass & profile as a prefabricated component), the installation can be optimally planned as part of a construction process concept. The glass installation itself usually takes place only in the course of the completion work. The glass and all the surfaces that are visible in the final construction are thus optimally protected against building contamination and construction damage.

GM RAILING® is completely and extensively tested with glass and profile, prefabrication is automated and manufacturing takes place with the highest process accuracy with a production line manufactured using special mechanical engineering. For this reason, it usually makes no sense to supply only sub-components. The choice of glass type and the required glass thicknesses correspond to the series and requirements. You are relieved of this selection, the verification of the quality and the static and production relationships with a complete delivery of GM RAILING® by Glas Marte.

PRICES OF THE DIFFERENT GLASS RAILINGS

While the cost of stainless steel railings with glass filling often starts at € 500 per metre, a general price for railings that are made almost entirely of glass cannot be given. The costs depend on the order quantity, the material to be used, the construction situation on site and the static requirements. The pure material price of an all-glass railing – i.e. fastening, connection to the building, substructure profile, glass profile, adjustment options, cover panels inside and outside, glass and handrail – often amounts to between € 250 and € 700. However, it is also easy to achieve the said sum for the handrail alone, for which a certain type of wood or geometry is desired.

How do you obtain the price of a GM RAILING® all-glass railing?

We will be happy to provide you with an individual price quotation for your construction project. You will then receive an exact price for your specific application in the shortest possible time. As a registered customer, you also have the option to use our online calculator for GM RAILING® UNI for calculation. You can find it in our service portal.

WHAT SCOPE OF PERFORMANCE DOES GM RAILING® OFFER?

- Advice on planning and implementation

- technical drawings or text descriptions

- Quotations

- Location-based clarification

- Work planning and execution planning

- Submission of approval plans

- Static proofs abP (general building authority test certificate) and quality assurance

- Individual production on the basis of the granted approval

- Manufacturing and delivery

- Installation or installation support also on request

INSTALLATION OF THE ALL-GLASS RAILING IN 2 STEPS

The GM RAILING® railing series enables linear mounting without uprights due to prefabricated glass construction modules in combination with a substructure profile and a continuous handrail.

The prefabricated glass construction modules are hooked into the substructure profiles to be installed on the construction site and screwed together with cylindrical headed screws or special spacers. This screwing allows a tolerance compensation of the vertical position at tie-bar height. Due to clamping in the support rail, no glass holes are necessary. This reduces planning and installation work as well as costs. Systematisation can generate benefits in all areas.

Whether executed as a lateral or flush-mounted installation – the GM RAILING® all-glass railing series offer the right solution thanks to their elegant, transparent appearance.

SAFETY WITH YOUR GLASS RAILING

GM RAILING® test certificates – patented, tested hundreds of times, internationally recognized

Glass railings must comply with the building regulations of DIN 18008. According to DIN 18008, the effects of damage to any parapet element (including the failure of end panes) must be demonstrated. In the event of failure of a parapet element, especially in the case of interaction of handrail and broken glass, this can best be demonstrated by means of tests, since the results of breakage tests differ drastically depending on the glass selection (LSG made of 2 x TSG or LSG made of 2 x HSG or LSG made of 2 x float glass) and foil thickness.

The broken glass has a residual stability or a residual load-bearing behaviour. Depending on the type of glass, this can have a positive or negative effect on the overall system. To date, we are not aware of any method by which the residual stability of broken glass can be proven conclusively by means of calculation.

For this reason, GM RAILING® has carried out hundreds of glass breakage tests with original components up to a single length of 4 m.

In-house test laboratory for glass railings

Breakage resistance, stability, load-bearing capacity and residual stability are just a few of the many parameters that we constantly keep an eye on and test in our test laboratory. In addition to high qualifications, the basis for this is the appropriate equipment of different test benches. In addition to the classic impact test, residual stability, breakage resistance, reaction to tension and pressure as well as stability of holders and suspension profiles are tested, recorded and logged with DKD-calibrated test machines. GM RAILING® is subjected to regular material and component testing by internal and external testing bodies.

WHICH GLASS RAILING?

Technical and visual support

We work with CAD-assisted software that makes it possible to make complex drawings with hatching, dimensions, texts, approval plans, parts lists, etc. for you as a 3D visualisation. In addition, drawings are output to a plotter or individual parts such as profiles are statically calculated. The most complex tasks can be solved in this way. Quality assurance, high flexibility and the graphical simulation of processes represent a high competitive advantage. In addition to the purely technical development work, GM RAILING® has also put a lot of work into supporting planners and architects. For instance, in addition to supporting bid documents, there are corresponding enquiry forms, planning aids and detailed drawings for each application.